Harbour Master

Harbour Masters

Worldwide there are approximately 3,000 merchant ports and the work of the Harbour Master can vary widely from country to country and from port to port even within the same country.

A propeller technology capable of substantially reducing the underwater radiated noise (URN) generated by ships’ propellers has been developed by Oscar Propulsion Limited and the University of Strathclyde, Glasgow.

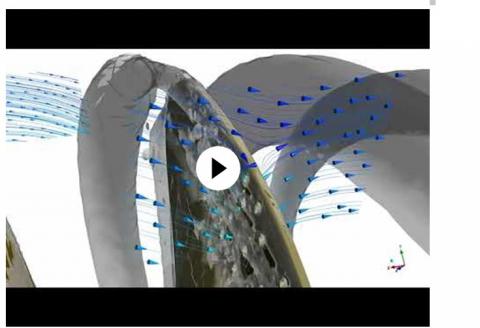

Known as the patented PressurePores™ system this reduces propeller tip vortex cavitation by applying a small number of strategically placed holes in the propeller blades. The addition of these pressure-relieving holes allows ships to operate with a more silent propeller.

Lars Eikeland, Marine Director, Oscar Propulsion, commented: ‘Underwater radiated noise is one of the most adverse environmental by-products from commercial shipping, yet unlike other forms of marine pollution, there is currently no international legislation in place to prevent or reduce this source of environmental damage.

‘Increasing noise levels, especially in the low-frequency range, is disorientating marine fauna and disrupting their communication signals, leading to behavioural changes or extinction. We now have a cost-effective, easy-to-apply solution that prevents this from happening.’

Dynamics modelling

Following four years of comprehensive computational fluid dynamics (CFD), modelling and cavitation tunnel tests during the solution’s development phase at Strathclyde, it was demonstrated that PressurePores can reduce cavitation volume by almost 14% and URN by up to 10dB.

Results were further verified in tests on the sub-cavitating propellers on Princess Royal, a 19m research catamaran operated by Newcastle University. And last year, CFD Finite Element (FE) propeller stress tests were successfully completed in accordance with classification society DNV rules.

Eikeland added: ‘We have found the optimum number of holes required to reduce the noise. So long as the right number of holes are placed in the most effective positions, a cavitation sweet spot can be achieved.

‘It is not a case of simply drilling holes into the blades, as this will affect the propeller’s thrust capability. We know exactly where to place the holes for maximum efficiency and for optimum noise reduction.’

It is interesting to note that propeller cavitation can generate as much as 188dB of underwater radiated noise and can be heard by marine fauna 100 miles away.

According to the US National Oceanic and Atmospheric Administration, anything above 160db can pose a significant risk to marine life.

Commenting on the impact noise has on marine life, Eikeland reflected with: ‘Noise levels in the ocean due to maritime activity has been increasing for decades and expected to double by 2030. URN can cause irreversible damage to marine wildlife through stress, habitat displacement, reduced reproduction, lost feeding opportunities and even death, greatly changing the marine ecosystem and impacting biodiversity.’

Eikeland concluded by saying: ‘PressurePores has a major mitigating effect on propeller cavitation and URN and can be incorporated into new propellers or retrofitted to existing propellers either in drydock or possibly in-water.

While Oscar Propulsions technology is suitable for all types of vessels, it is understood that it is particularly suitable for naval vessels, yachts, fishing fleets, offshore vessels and cruise and research vessels operating in sensitive environments. The technology can be applied to all types of propellers, including pods and thrusters, it has been reported.

Click below to view a YouTube video showing the Oscar Propulsion’s patented PressurePores

Founded in 2017, MarineLabs delivers high-resolution, real-time, and historical wind, wave, and weather data, as well as hyper-local 10-day forecasting, from a growing network of cloud-connected, rugged sensor nodes.

The International Harbour Masters Association (IHMA) and the Port of Rotterdam Authority are pleased to announce the 15th International Harbour Masters Association Congress, to be held from 09–12 June 2026 at Theater Zuidplein in Rotterdam.